Monel K500 alloy in addition to having a high strength, corrosion resistant, non-magnetic excellent mechanical properties, but also has the same corrosion resistance of Monel 400. Can be used as the pump shaft material, working under harsh high-sulfur, high wax layer geological mining conditions. Not plastic - brittle transition temperature of the alloy, it is ideal for a variety of cryogenic equipment. This alloy is mainly used for the pump shaft and a valve stem, the conveyor scraper, oil well drilling ring, the elastic member, the valve pad. Applicable to the petroleum, chemical, shipbuilding, pharmaceutical, electronics department.

Chemical composition

The alloy chemical composition substantially the same as with the Monel 400, the biggest difference is containing 2.3-3.15% Al and 0.30-1.00% Ti, the microstructural characteristics of this alloy except for dispersion of Ni3 (Al, Ti) precipitates precipitated outer other Monel 400.

Corrosion Resistance

The general solution state Monel K500 corrosion resistance Monel alloy 400 is basically the same, about the corrosion resistance of Monel 400 can apply to Monel K500 alloy. As the low corrosion rate of the alloy in flowing seawater and high strength of the alloy, so that the alloy is particularly suitable for manufacturing centrifugal pump shaft seawater corrosion resistant.

Mechanical behavior

No plastic - brittle transition temperature of the alloy, it is very suitable for the manufacture of a variety of low-temperature equipment, welding can improve the strength of the alloy, but reduces the ductility of the alloy. Accordingly, in order to maintain the high plasticity, solder alloy Monel K500 need for heat treatment.

Product Application

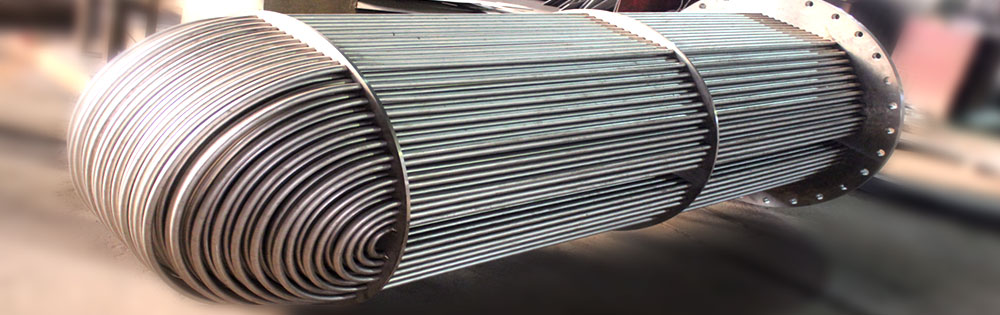

Pump shaft and impeller

Conveyor scraper

Oil well drilling ring

Elastic member

Valve pad

TEL:+86-0917-3388668 3388938

FAX:+86-0917-3388937

Manager:MR Kou

TEL:+86-13609174292

MAIL:zbtkqh@163.com

2014-2016 Baoji Zhong Bao Tai Metal Co., Ltd.

2014-2016 Baoji Zhong Bao Tai Metal Co., Ltd.